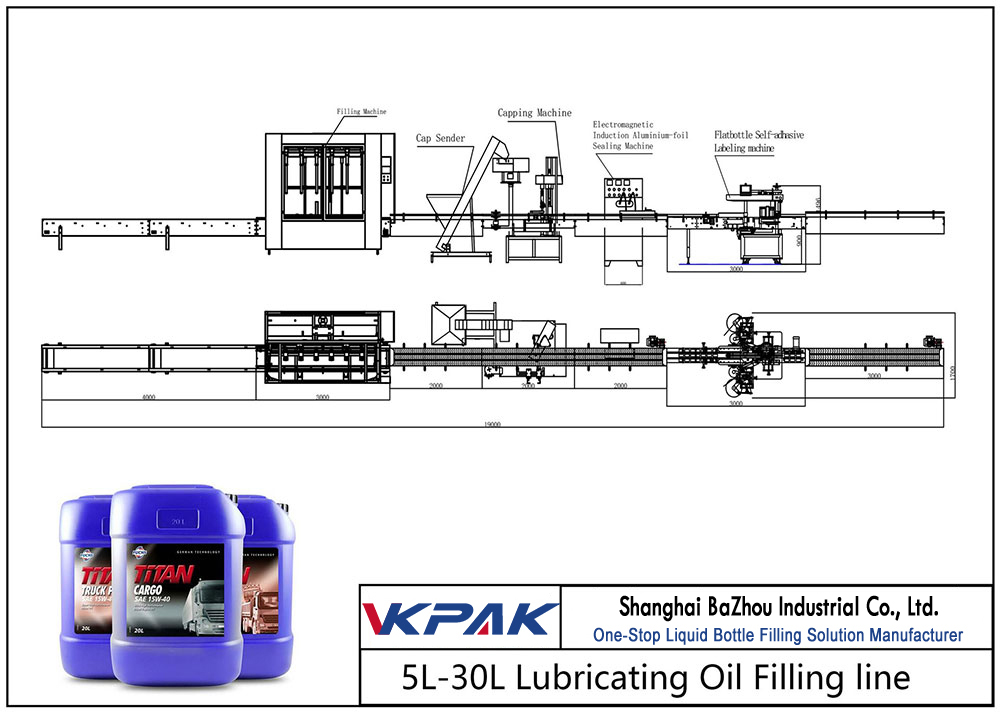

Automatic 5L-30L Lubricating Oil Filling Line

- This Automatic 5L-30L Lubricating Oil Filling Line comes with everything you need to get your liquid sweetener bottling line up and running. It is designed to bottle 10 bottles per minute.

- Filling Line Details

Line Name: Automatic 5L-30L Lubricating Oil Filling Line

Automation: Automatic

Filling volume: 5L-30L

Bottles Per Minute: 4-12 - Machines Included

Automatic Weight Filling Machine

Automatic Capping Machine

Automatic Labeling Machine

- 1.1 This weighing filling machine is for filling 10kg to 30kg liquid.

- 1.2 Each filling head has the weigh and feedback system, each filling head can be regulated.

- 1.3 This type filler adopts PLC to control, touch screen control panel.

- 1.4 It applies dive method to fill and it reduces foam.

- 1.5 It automatically achieves counting inlet bottle, gravity filling, and bottle outlet. It is especially good for filling SL, edible oil and lubrication. It is a nice choice for foodstuff pharmacy, cosmetic and chemical industries.

- 1.6 Each filling head has the weigh and feedback system, each filling head can be regulated.

- 1.7 Photoelectric sensor, approximate switch and other electric elements are of the international famous brands. It ensures no container miss filling. The host machine will alarm if there is any container blocked.

- Technological parameters

- 1 Number of filling Head: 4

- 2 Filling range :10-30kg

- 3 Bottle size range :

L: 160mm~360mm W: 140mm~260mm H: 250mm~500mm

(Min: 140 × 200 × 320 mm , Max: 260 × 290 × 500 mm) - 4 Diameter of bottle mouth:≥Φ40mm

- 5 Power Supply: ~ 220 V, 50 Hz

- 6 the total power: 1 kW

- 7 Weight: about 1250 kg

- 8 measurement accuracy: ± 0.2% (Note: Filling accuracy depends on the viscosity of the material as well as the continuity and stability of the material supply);

- 9 Production capacity: 400-500 bottles/hour for 4 filling heads for 20L

- 10 Outline Dimension (L×W×H):2500mm×1000mm×2526mm for 4 head